Vertically integrated manufacturing offers 100% control over processes and quality while shortening lead times.

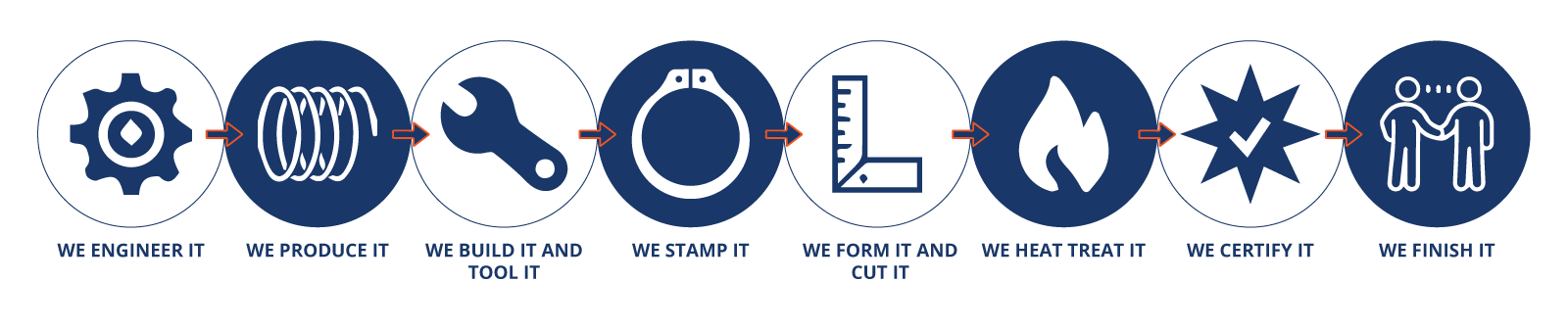

Our Process

Our goal here at Rotor Clip is to continuously produce and deliver high quality, precision parts with tight tolerances that our customers can count on. In order to meet this goal, Rotor Clip has taken every critical production step and support process in-house. This total vertical integration allows for a very high level of quality control, process optimization, and innovation when it comes to manufacturing retaining rings, wave springs, and hose clamps. Additionally, this level of integration improves lead time management and provides us with more flexibility to quickly react to changing market demands, as we are not dependent on the capacity of other 3rd party companies.

Over 60 years of fine tuning our internal processes to produce retaining rings, wave springs, and hose clamps has made us experts at everything we do at every step in the production process. Starting with raw material, multiple wire mills with no-contact laser gauges ensure only precision wire made from carbon/stainless steel and exotic alloys with very tight tolerances is used during production of flat wire products and ensure that product is ready to ship in a short period of time.

Our tool making departments at both of our manufacturing locations are staffed with expert craftsmen and equipped with state of the art tool making equipment. Our experienced and skilled toolmakers build and maintain hundreds of tools each year that shape wire and strip steel into millions of precision ring, spring, and clamp solutions.

With the emergence of IoT, our production equipment has evolved into smart stamping presses and coiling machines that continuously monitor tooling conditions and product output. Predictive and preventative maintenance measures tied directly to our ERP system have signicantly reduced machine downtimes and production slow downs. This guarantees maximum production runs, improved Lean manufacturing efforts, reduction in raw material waste and additional quality control. The end results are high quality products for our customers delivered on time.

Rotor Clip operates several in-house heat treating in-house heat treating and annealing furnaces. Each hardening and annealing process is finely tuned to produce the metal grain structures and characteristics needed for high performance retaining rings, wave springs, and hose clamps used in safety critical applications.

Our internal finishing operations produce corrosion protection options for a variety of industries and operational environments. From shelf life to 240+ salt spray hour protection, our quality finishes combined with expert advice will guarantee that applications are properly protected and long lasting. We continuously explore new finishes that offer the necessary corrosion protection, while having little to no impact on the environment.

Rotor Clip’s integrated manufacturing expertise in conjunction with our in-house quality and metrology labs ensure that our customers receive only high quality retaining rings, wave springs and hose clamps, at competitive prices, delivered on time.