Retaining Ring FAQ's

ANSWERS TO SOME OF OUR MOST FREQUENTLY ASKED QUESTIONS ABOUT RETAINING RINGS

What is a retaining ring?

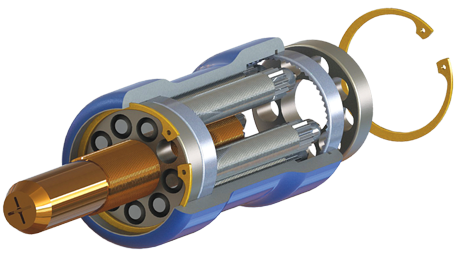

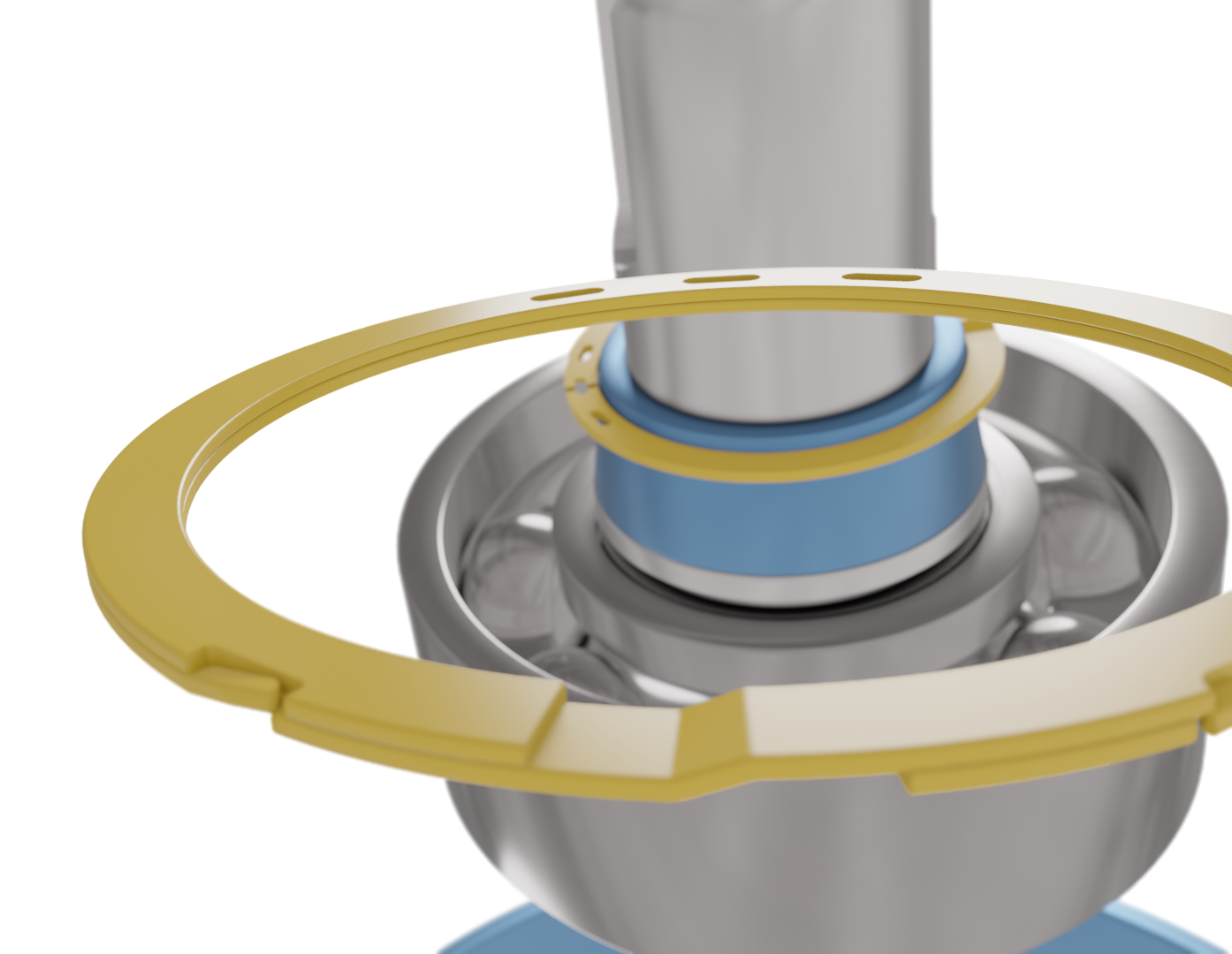

Retaining rings — also known as circlips and snap rings — are metal fasteners installed into a groove on a shaft or in a housing or bore to retain an assembly. They keep parts in place using a compact, lightweight design that requires fewer machining operations than other fastening techniques. Engineers specify retaining rings based on their installation and removal needs, rotational speed of the application, expected force loads on the ring, the conditions of the operating environment, and cost.

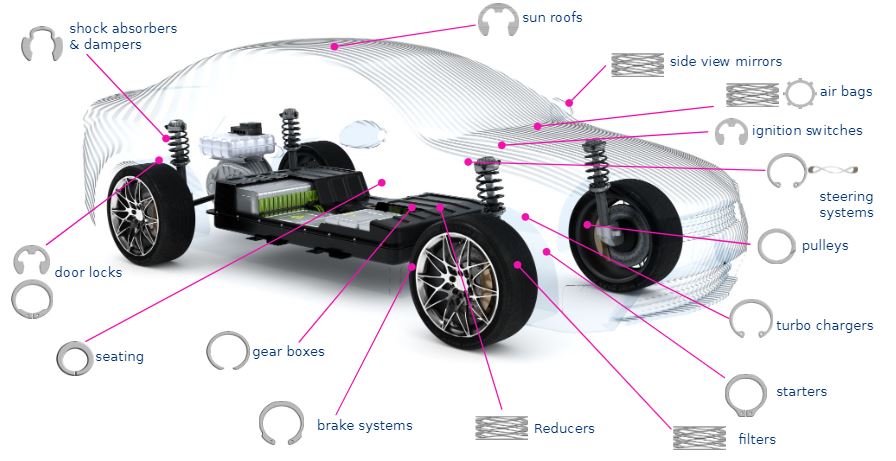

Retaining rings can range in size from 1mm to 1m in diameter, and the potential combinations of size, shape, style, and material result in designs that work in a wide variety of industries and applications. A standard automobile, for example, can have well over 50 circlips spanning systems from steering to power train to passenger safety. Retaining rings are used in myriad other applications including gym equipment, wind turbines, bearing retention, bicycles, door knobs, gas pumps, office equipment, and more.

-1-1.png)

What retaining ring styles are available?

Rotor Clip manufacture over 50 styles or rings with over 1000 part numbers, with custom capabilities, meaning there is a unique retaining ring to fit every application. To simplify things, they can be sorted into three main categories by their design attributes.

Tapered-section rings decrease in width from the top of the ring to the free ends. Installed, they make continuous contact within their installation groove. Some tapered-section rings designed for axial installation feature lugs that make them easier to expand and place.

Constant section rings (snap rings), in contrast, have the same width throughout their circumference. The resulting stiffer cross section results in contact at three points within the installation groove. These simple, easy-to-produce rings typically do not have lugs.

Spiral rings are made from flat wire coiled two or three times around the circumference. They make 360° contact within their groove and have a constant width around their circumference. Spiral rings are not usually designed with installation lugs. Instead, they may have notched ends that aid in their removal.

.png)

Where are retaining rings used?

Retaining rings can range in size from 1mm to 1m in diameter, and the potential combinations of size, shape, style, and material result in designs that work in a wide variety of industries and applications. For example, a standard automobile, can have well over 50 retaining rings, spanning systems from steering to power train to passenger safety.

Retaining rings are used in myriad other every day or highly specified applications including gym equipment, wind turbines, bearing retention, bicycles, door knobs, gas pumps, office equipment, and much more.

How do I know if I'm choosing the right retaining ring for my application?

We have been manufacturing retaining rings since 1957, so have the highest level of expertise to help guide you and ensure you are selecting the best retaining ring option for your unique application. We don't offer a one size fits all solution and have over 50 different ring styles to choose from as well as custom capabilities should you require them. Specific application requirements, installation practices, and budget are all factors to consider when choosing a retaining ring style. For a balanced review of your options, selecting a manufacturer, like Rotor Clip, will mean we find the right ring for you. Visit our website www.rotorclip.com or schedule a consultation with one of our expert engineers to get help choosing the best retaining ring for your application.

Want to take a look for yourself? Why not download our whitepaper, Technical Considerations for Selecting a Retaining Ring.

Which ring can handle the high speeds and high force applications?

When choosing a retaining ring style, you’ll want to take the demands of your application into account, so be sure to check each style’s ratings.

Some styles of tapered section rings available have significant radial spring force that can handle high RPM applications and high loads.

Spiral rings also work well with high loads, especially in applications where resilience to dynamic loading is needed. They are considered to have lower RPM capabilities than tapered section rings. However, Rotor Clip's patented locking feature can solve this, by keeping the product tightly in place. Spiral rings are also well balanced and are available in materials and styles ranging from light duty to heavy duty based on the force load you need to retain.

Though constant section rings are typically used in applications with lower load and speed requirements, don’t overlook them. Several constant-section styles are available that can bear significant loads at an attractive price point.

Which rings meet my installation and removal requirements?

Consider your preferred installation method and the frequency with which you’ll be installing and removing the rings. For instance, the lugs on axially installed tapered-section rings make them easy to install and uninstall with commonly available tools like retaining ring pliers. Keep in mind, designers must ensure they leave clearance for the lugs and room for the pliers to fit within the design.

Constant-section rings (snap rings) are manufactured to ensure a controlled edge condition on the mating surface for less wear from sharp edges. The absence of lugs gives this style a low clearance but requires a tapered mandrel or cone for installation.

Spiral rings are also free of sharp edges. They are the most difficult to install, usually via a tapered mandrel or cone, but they have the lowest clearance of the three style types. Spiral rings are usually the best for tamper-proofing; choose an end type that makes them quite difficult to remove. Or, for easier removal, choose an end type that renders the spiral rings easy to remove with a flat-head screwdriver.

.jpg)

-1.png?width=150&height=150&name=Untitled%20design%20(17)-1.png)

.png?width=150&height=150&name=Untitled%20design%20(16).png)

.png?width=150&height=150&name=Untitled%20design%20(20).png)

-1.png?width=150&height=150&name=Untitled%20design%20(19)-1.png)