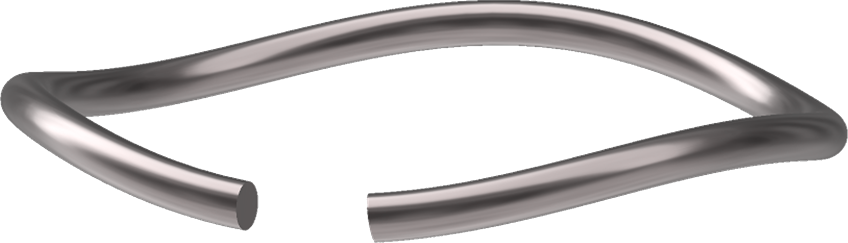

SRT Round Wire Wave Springs

Standard sizes from 0.5" through 6" (12.7 - 152.4 mm)

Customs on request, with no tooling costs.

SRT Wave Springs are designed for use in high load, high rate, low deflection, static or low cycling applications. Cost effective replacements for disc springs.

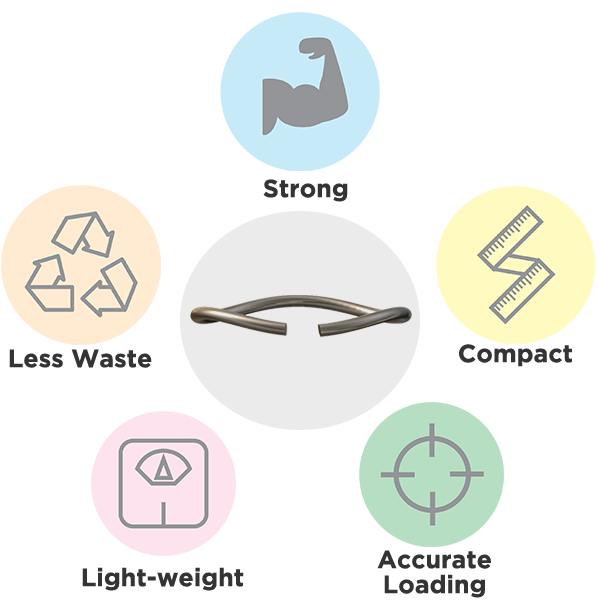

Strong:

Increased loading capacity vs. flat-wire wave springs

Accurate:

More accurate loading capacity vs. traditional springs

Compact:

SRTs offer reduced radial space vs. traditional springs, flat-wire wave springs, and disc washers.

Light-weight:

Less material is used making a round wire spring, allowing for a lighter weight product.

Less waste:

Because SRTs are coiled and not stamped, there's less waste. This is especially important for pricey alloys for custom parts!

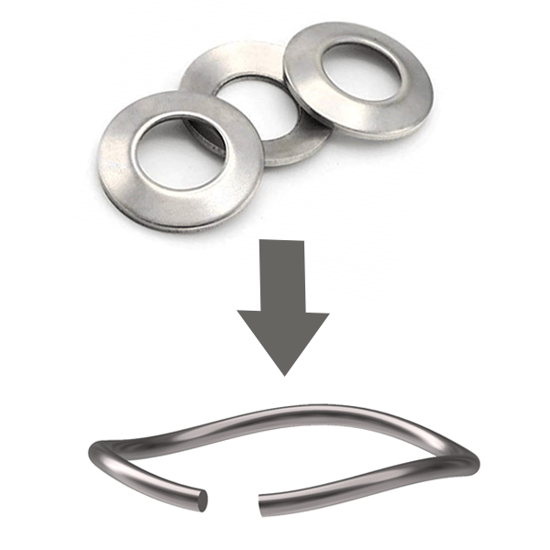

Are you still using disc springs? Stacks of disc springs?!

Optimize your application performance with SRT!

Round wire wave springs offer comparable compression loads, but with the additional benefit of improved load accuracy and up to a 25% reduced radial cavity.

The significantly reduced section width reduces the required radial space, thus benefiting overall component size and weight which can be critical design considerations.

Only one SRT needs to be assembled compared to stacks of disc springs offers peace of mind and reliability in application maintenance and manufacture.

In addition, the spring is coiled not stamped from sheet material; therefore the metal grain stays intact for a stable product, reducing environmental impact by decreasing waste and making it a more cost-effective manufacturing option.

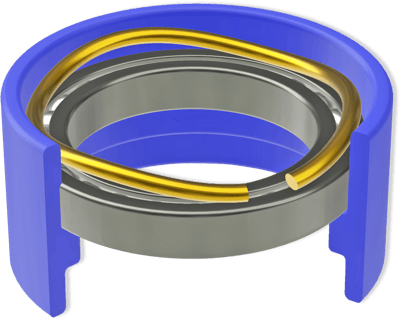

SRTs are a versatile product and are crucial in:

Heavy-duty clutches

Ball valve seats

Bearing pre-loads (as shown here)

Hydraulic or pneumatic directional control valves

World Manufacturing and Headquarters is in the United States, with additional manufacturing and logistics in the Czech Republic. Rotor Clip owns a local warehouse and distribution center in the UK with additional sales, engineering and customer service for the UK market. Rotor Clip also has sales offices in Germany and China.

Rotor Clip USA recently opened it's 4 MW solar field, allowing us to become 75% operational on solar power!

Rotor Clip Manufacturing Facilities are certified to IATF 16949, ISO 9001, ISO 14001, and AS9100.